Strategy, Legal & Operations

6 ways to optimise inventory management in the food production industry

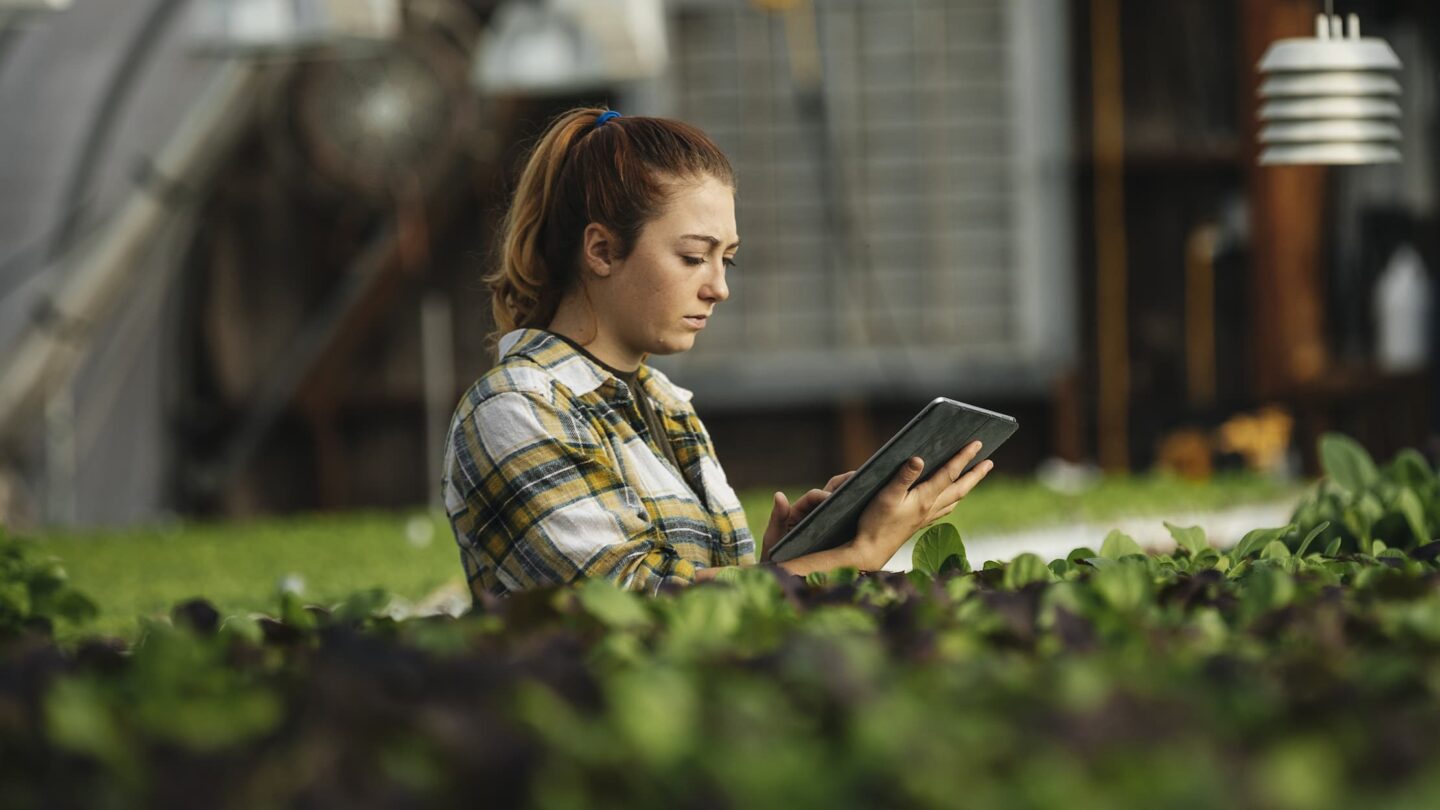

Learn about six ways you can step up and improve inventory management for your food and drink manufacturing business.

Why is inventory management important?

Coronavirus affected food and drink manufacturing supply chains around the world, with lockdowns across the globe causing customer demand to fluctuate.

Consumers created sudden spikes in demand for certain goods, forcing food manufacturers to increase supply and modify their inventory.

The food and drink manufacturing business is unique in that stock is most often perishable, requiring the supply chain to be managed in a way that ensures delivery of products while ensuring the safety of consumers.

Understandably, the food and drink industry is highly regulated, which means food needs to comply with health standards, and certainly needs to be removed before it gets old enough to cause harm to consumers.

The most effective and efficient food and drink supply chains need excellent inventory management – the process of supervising the flow of goods from manufacturers to warehouses – to the point of sale.

This includes the management, warehousing and processing of finished goods, raw materials, components, and finished products.

It’s a critical component of supply chain management, and necessary for any business involved in buying or selling products.

Improving inventory management requires increasing command of your warehouse operations and the physical stock inside it.

Below are some areas you can work on right away that will improve your inventory management. Here’s what we cover:

1. Evaluate your current practices

2. Perform routine stock reviews

3. Learn customer behaviour and take advantage of big data

4. Optimise stock replenishment

5. Ensure faster product recalls

1. Evaluate your current practices

Before you can make improvements, take an overall look at your practices.

Effective inventory management is purpose-driven. Understand what each link in the chain does – this allows you to focus on the specific aspects of your system that need improving.

Consult with other members of your team to identify potential problem areas and start there.

In food and drink manufacturing, there are seven waste areas to identify that you could focus on in reworking your inventory processes:

- Minimise overproduction by increasing visibility and controls to align production, purchasing, and logistics.

- Avoid too much inventory with demand planning and modelling tools to support just-in-time production.

- Eliminate waiting by providing staff with the access they need to streamline decisions and approvals with automation.

- Solve transport problems by timing production and logistics, avoiding moving goods from one place to another needlessly.

- Prevent over-processing and focus on actions that only create value – such as the creation of a bill of materials.

- Stop unnecessary motion by providing data that ensure your machinery is working in the most efficient, productive, and effective way.

- Put controls in place to wipe out defects, acknowledge where the deviations are, and stop them at the source.

2. Perform routine stock reviews

A significant part of inventory management is simply knowing how much of each item you have in stock.

Tracking what you bought against what you sold will not give you the full picture. Food and drink items can get lost, stolen, or damaged after they enter the warehouse. It is unavoidable.

Often, lost items go unreported until the right person takes notice.

Remedy this problem by routinely reviewing your physical inventory for accuracy with your records.

3. Learn customer behaviour and take advantage of big data

One significant benefit of using big data is its ability to make accurate predictions, which could considerably boost inventory management.

Throughout the year, customers often show different buying habits for food and drink products. Some of these can be more obvious, relating to seasonal holidays such as Christmas and Easter, but sometimes there are changes that businesses won’t catch without data analysis.

To avoid having too much or not enough inventory, businesses can rely on data technology to stock items at the right time.

Keep track of how often you are restocking certain items and try to identify any trends or patterns – there may be seasonal or other outside factors that affect your product flow.

Note the periods when customers are ordering more, and when they are ordering less. Having a solid handle on how your customers behave allows you to stay ahead of the dry spells and mad rushes, so you maintain the right inventory balance.

If you are involved in food and drink manufacturing and have been looking at ways to win a competitive edge on your competition, you may have already been looking at inventory management software that can automate key business processes and power insights, helping you to make better data-driven decisions.

Big data can improve efficiency in inventory management by flagging problems that you might not even know had existed.

By collecting information from tools and Internet of Things sensors, you can quickly pull information detailing any processes or machinery that are not working at maximum performance, or provide guidance for when something is due to repair.

4. Optimise stock replenishment

Having a system in place for restocking your inventory ensures you are never entirely out of stock.

It is crucial for the smooth flow of product during busy periods. Food retailers have been known for using just-in-time manufacturing strategies, where supplies are replenished each day based on sales and forecast demand, meaning supermarkets can maximise food shelf life.

If you are not using the just-in-time strategy, you should have a policy to replenish inventory at set levels. Anytime the stock of an item falls below a certain number, you should get the order in.

Systematising the replenishment process can avoid a lapse in product availability between the time you order and receive the shipment.

In the past, you may have had to check inventory manually, making decisions to reorder based on guesswork. Now technology is there to allow you to analyse trends that can reveal which products aren’t selling and alert staff to when they need to start reordering more of a certain product.

5. Ensure faster product recalls

Sometimes the worst happens, and you may have to recall a food and drink item. If handled poorly, it has the potential to cause permanent damage to your brand, so you need to act quickly and ensure minimal damage.

Having up-to-the-minute data to answer these questions, you can quickly identify exactly where the problem lies, and address the issue with confidence, provide market reassurance, and mitigate recall cost.

To gain data access in real-time, you must store data centrally, allowing you to track data from the furthest reaches of the supply chain in, through the production process, and from customers.

Information travels fast.

Consumers can access potential food and drink product problems as quickly as anybody publishes it. A poorly handled product recall can damage the reputation of your business, sometimes irreparably, so you need to control the narrative.

The safest and best strategy is for your food and drink business to communicate with authenticity that you are in control of the situation, and that you have the right solutions in place.

6. Reduce food waste

Your customers are more environmentally aware of the issues created by food waste. It will pay to invest in inventory management technology that can reduce excess inventory and handling, ultimately cutting down on the perishables that go to waste.

A first port of call is to ask retailers to share data that can not only help you with your production plans, increase efficiency, and promote quality – but promote a green agenda.

Investigate, also, how surplus product can be reused in some way – for example, through charitable organisations. Misshapen or imperfect food, for example, which supermarkets might usually turn away, could be sold for a discount.

Ask the author a question or share your advice