How your business can avoid supply chain problems by investing in the right tech

KFC running out of chicken was a national news story, with the fried chicken restaurant forced to temporarily close of hundreds of its branches. It became a hashtag on Twitter – #KFCCrisis – with even Tower Hamlets Police in London needing to send a message out to tell people a shortage of fried chicken was not actually […]

KFC running out of chicken was a national news story, with the fried chicken restaurant forced to temporarily close of hundreds of its branches. It became a hashtag on Twitter – #KFCCrisis – with even Tower Hamlets Police in London needing to send a message out to tell people a shortage of fried chicken was not actually a police matter.

It’s easy to find humour in this story – and of course it resulted in many chicken-related puns. But the KFC incident is an interesting business case study on how supply chain problems can occur.

It’s also a warning to food manufacturers and distributors about worst-case supply chain scenarios and the amount of money that could disappear due to lost business in the event of something going wrong.

The Colonel is working on it. pic.twitter.com/VvvnDLvlyq

— KFC UK & Ireland (@KFC_UKI) February 17, 2018

So what happened that caused KFC to run out of chicken? The problem at its core was around distribution – a new delivery partner in DHL said it was having “operational issues” that resulted in supply disruption. DHL, along with a software partner in Quick Service Logistics (QSL), had replaced South African-owned company Bidvest.

Samir Dani, Professor of Logistics and Supply Chain Management at the University of Huddersfield’s Business School, told Wired that operating out of one single warehouse may not have helped matters.

He said: “Companies may operate out of one warehouse, but you have to think about the product. There are legality issues around the quality of the produce and the contamination that can happen is not handled properly. That’s the problem with food – distribution can’t be thought about like any other supply chain.

“Serving the length and breadth of the country from one warehouse is a complex task anyway. The fact that it was a new warehouse, new IT system and the handover was just happening makes this a perfect storm.”

“Number of elements” caused the issue

However, Richard Wilding, Professor of Supply Chain Management at the Cranfield School of Management, believes the full cause of the crisis was more complex. He said: “Using a single location will not be the lone cause of this particular problem at all.

“There will have been a number of elements which have come together. Demand, automation in the facility, the planning software, all those sorts of things interacting together. There may be a particular cause which will come out of this, but pinpointing that may be a tricky thing.”

Without knowing the full detail of why the situation occurred, it’s still worth food and drink manufacturers and distributors looking carefully at their own business processes, to reduce the chances of a similar supply chain situations occurring for them.

Food and drink manufacturers need to go all-in with data

All food and drink manufacturers are dealing with huge cost pressures and razor-thin margins. They need to forecast accurately and deal with changes in demand, forced by changing customers and other economic pressures.

Many are starting to recognise that the vast amount of data generated from their daily operations and the products they make can be turned into insights, making for a significant economic advantage.

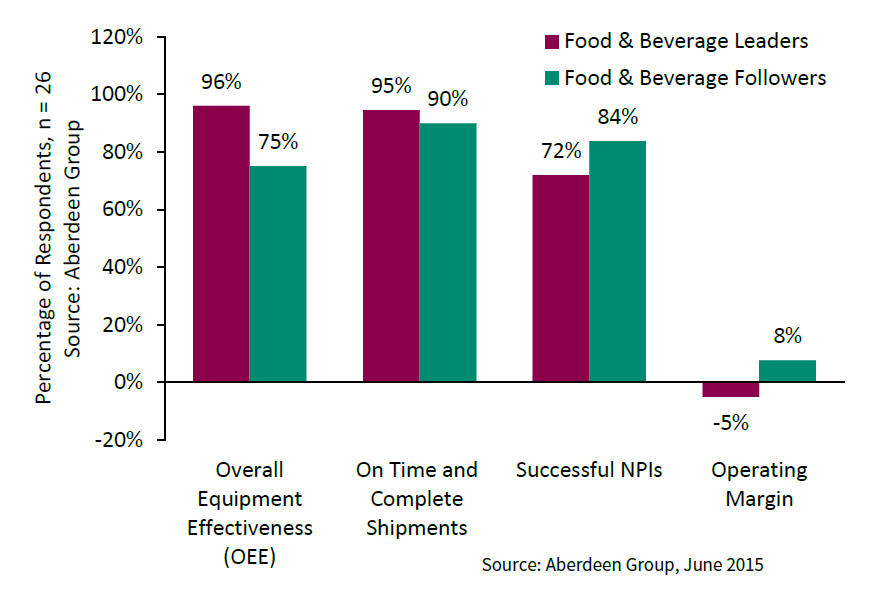

Take a look at the difference that data makes, with food and beverage leaders far outperforming their peers.

Source: Data will drive the future of food production, Aberdeen Group

Because of data, food and drink leaders outperform less data-focused businesses in terms of plant efficiency, customer service and innovation. Since they can use data better, they can make better decisions and have increased agility when managing operations. This allows them to deliver higher quality products at lower prices.

As a food and drink manufacturer, you should also look at enterprise systems, which can help you manage huge amounts of complex product and operational data.

This gives both manufacturer and employees the ability to connect day-to-day operations and their overall business goals. ERP systems are available that can forecast and report production, consumption and fulfilment, reducing spoilage and cost by improving efficiency.

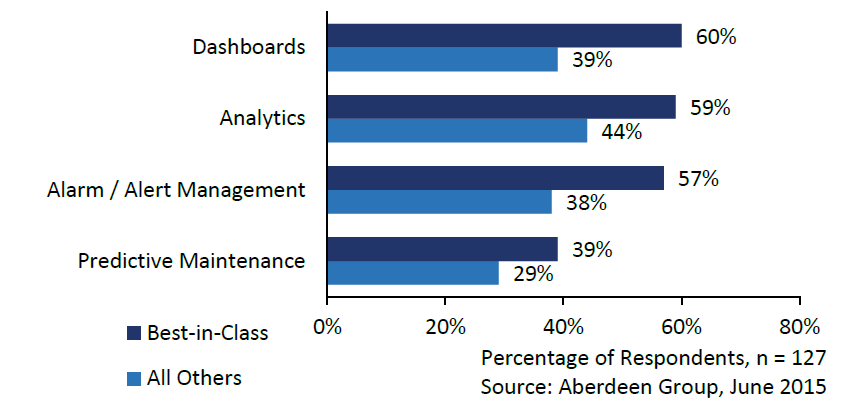

You should also think about the tools you’ll use to turn the data you have into actionable intelligence.

Source: Data will drive the future of food production, Aberdeen Group

This is valuable for your supply chain needs because analytics can provide intelligence for when a problem might occur, and even provide direction on how to resolve that issue.

A combination of analytics, alerts and dashboard models can automate the collection of data, analyse and monitor it, and escalate issues to the right decision makers.

If you’re summarising data from multiple sides of the business, you can plan your purchasing, delivering and maintenance more efficiently, giving you the agility to cope with supply chain problems before they occur.

You can then think about moving away from a traditional manufacturing “siloed” approach, favouring full supply chain integration right to the point of delivery – perhaps by using the Internet of Things to transfer data collected from the shop floor to complement a centralised ERP system.

Distributors need to be equipped to meet customer demand

Distributors must meet the demands of food manufacturers and demanding customers without sacrificing their profit margin. The need to get the right food products, at the right place, to the right customers is vital.

This is critical important in the food industry, where the product is perishable and can only be stored for a certain amount of time. Reports indicated that the KFC chicken crisis resulted in chicken spoiling in depots.

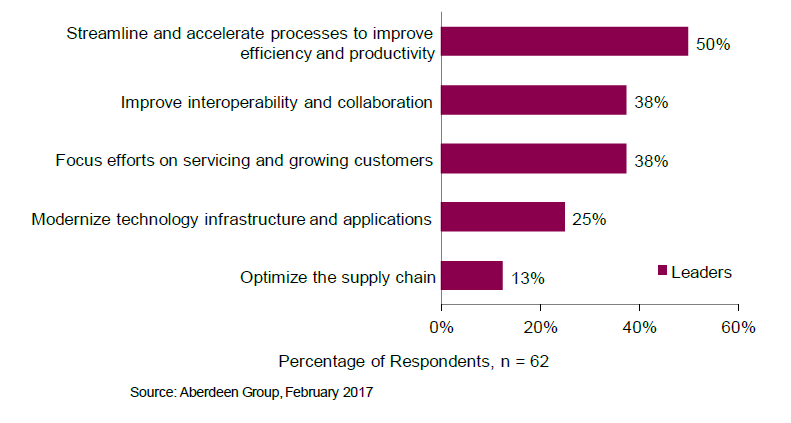

According to Aberdeen Group, these are the top strategies that leading wholesalers and distributors should be looking at to become better businesses:

ERP in Wholesale and Distribution: Improving customer interactions at a lower cost

If you’re a distributor, you can lower costs and improve margins by streamlining your processes and optimising your supply chains – managing inventory and keeping prices in check.

You must also prioritise collaboration and service, interacting with and understanding the customer, as well as their needs. This might mean changing the way your deliver products, which would require changes in workflow.

However, legacy systems often make it hard for distributors to implement new delivery methods, as well as increase interoperability and efficiency. That’s why it is necessary for distributors to modernise the technology that they use to support their operations.

This could involve new ERP systems, integrated with technology such as CRM and real-time analytical capabilities.

Peter Laplanche, a director at Datatrade, said that when it comes to managing supply chains, an efficient warehouse was paramount for the smooth running of an operation.

He said: “It’s not just about products being stocked and logged properly, it’s also ensuring they can be easily located to be shipped as efficiently as possible.

“Flawless fulfilment, as it has been known, has served the purpose of computerising in real time the tracking and checking of products as they pass through picking, packing and despatch.”

With ecommerce growing and firms moving products around a network of warehouses and stores, Peter believes there was a need for a more interconnected and transparent fulfilment process.

Avoid supply chain problems with smarter, efficient systems

He said: “Intelligent fulfilment, while still in its infancy, offers promise that artificial intelligence [AI], automation, machine learning and the Internet of Things can be brought together to create smarter and more efficient systems.

“Better visibility of stock and improved communication ensures items are available whenever and wherever they are needed.

“With such technology, operational managers could monitor the real-time status of stock levels and locations to anticipate and adapt product levels according to seasonal/peak demands, or changing weather conditions.”

According to Food Manufacture’s Online Supply Chain survey in 2017, 64% of reports said they planned to invest in supply chain operations over 2018. However, this is down from the 71% reported in 2016.

The KFC crisis shows supply chain problems can cause logistical issues and damage to the reputation of a business, comparable to the unwanted attention caused by a sizable data breach.

It shows the true importance of logistical operations, which should certainly not be neglected. Businesses would be wise to remember these lessons.