Growth & Customers

Here’s how customer experience takes the stress out of supply chain and inventory challenges

In this article, we cover the importance of placing customer experience at the heart of your business.

Today’s customers have ever-changing and ever-increasing expectations for good customer experiences, regardless of their sector. They want what they want when they want it. And with price increases across all markets, spending has increased too. And as people spend more, their expectations continue to rise.

As a result, your customers have come to expect a level of service that’s without friction, that’s founded on excellent communication, and that leaves them with a sense of being well looked after and valued by your business.

To nurture your customer relationships demands that you position their wants and needs at the heart of the customer experience your business provides. If each exchange you have can add long-term value, create a positive impact, and serve to differentiate you from the competition, you can increase customer engagement and satisfaction—and positively impact your bottom line.

Discover how to take the stress out of supply chain and inventory challenges

Download this free guide to learn how to:

- Prevent stock outs and overstocks

- Understand and prioritize your top-performing items

- Analyze your weeks of supply and sell-through velocity

- Implement location-based analysis across your items

- Hone your promotion strategy

- Be proactive in your internal and external communications

Nurturing and preserving your customer interactions

In today’s crowded marketplace, it’s worth reflecting on what you can do to ensure you’re meeting your customers’ needs to the high standards they expect. And thinking how you can make sure that any significant frustrations that are out of your control—like supply chain issues and inventory challenges—don’t leave you and your valued customers, high and dry.

Handling ongoing supply chain challenges

Today’s international supply chains are dynamic. Manufacturers and distributors are in control of if, when, how, and where to ship their goods, which means you can find yourself facing uncontrollable and unexpected delays, unpredictable lead times, unforeseen economic fluctuations, and increasing raw material and freight prices across every sector.

And when problems impact the bottom line in such a direct way, they can cause significant pain—and result in poor customer-supplier interactions. Add into this volatile mix a potential period of days, weeks, or months of port congestion, and you’ve got a recipe for disaster, both for you as a supplier and—at the end of the chain—your customers.

To manage this well, demands that you are resilient, patient, and that you excel at clear communication. And on a practical level, it might be a timely prompt to implement an inventory management application to relieve some of the stress and help you predict lead times with as much accuracy as possible.

Effective inventory, seamless business continuity

Supply chain issues notwithstanding, running any successful business demands that you fulfil your customers’ orders in time. Whether you rely on one or several warehouses, or on supplier drop-shipping, the backbone of your business needs to be a robust, well-stocked, and efficient inventory.

But, like trying to manage the supply chain, running an inventory brings its own set of challenges. Happily, there are practical things you can do to increase your resilience so you’re prepared and can thrive as and when these challenges strike.

Let technology take the weight

Let’s take the potential for a lack of visibility for starters. If you can’t find your customers’ items in your inventory, you can’t ship their orders. This is frustrating for everyone involved—and risks negatively impacting your reputation as a trusted supplier.

The answer is a proper system to help your pickers track products in the store, which can be introduced with technology that uses RFID barcodes or QR codes.

Invest in your people

And while we’re on the subject of pickers, one of the most common and repetitive inventory management challenges is inventory waste and defects—a problem that in time can lead to significant losses.

The answer is to invest in training for your warehouse staff so that your stock is looked after properly, waste levels are minimized, and you maintain your customers’ satisfaction with the service you provide.

A second way to support your staff and avoid problems is the development of a centralized inventory hub. This can save time and stress when it comes to stocktaking, prevent shipping delays, and simplify the job of tracking what’s going in and out of your facilities.

Invest in up-to-date software

Then we come to the risks involved in using manual procedures or outdated legacy software. What worked when you were starting out will certainly start to become less efficient, and could even implode as your business expands.

The software you use to manage your inventory needs to be scalable and secure, so it can expand with your business in times of plenty and be scaled back to adapt as and when times are lean.

Effective inventory management helps to make your business more efficient as it can help you plan and help you identify and dispose of the unsold or unused stock that results from overstocks, respond to, and forecast fluctuating consumer demand, and reduce expensive warehouse storage costs.

The need for customer-centricity

But what impact do such uncontrollable events like supply chain issues and inventory problems have on your customer? What happens when the items they want—or have bought and paid for—simply don’t show up? And is there a way to manage the relationship you have with them to ensure you nurture their ongoing custom, despite the immediate frustrations?

The invaluable power of communication

No one likes being let down, especially by a supplier you trust. And any initial feelings of disappointment, confusion, and frustration can be multiplied by external stresses.

Imagine a valued customer has ordered something from you and a supply chain delay at your end means one of their significant projects is put on hold. Perhaps they have to go and tell their boss that they’ve been unable to deliver on a commitment. Or one of their important customers loses patience and leaves them for a competitor.

All of these situations are uncomfortable and stressful—but in many instances, they can be avoided. Because when it comes to providing a high level of customer experience, much depends on your communication skills.

Uncompromising customer experiences

In times of stress, being able to meet customer needs with empathy, care, concern, and connection is crucial. This can mean something as simple as making a phone call to say you’re sorry. Being honest about the situation and listening to the impact it’s having.

And an irate customer is more likely to calm down and accept your apology and explanation if you can demonstrate that you empathize with their frustration and are doing everything you can to rectify the situation.

And this brings us to another area where it pays to invest in your people. On a wider scale, investing in the customer experience you provide can require that you hire and train a team of dedicated customer service staff.

Giving customers access to someone to talk to and to whom they can express their frustration can help reduce customer pain points and friction.

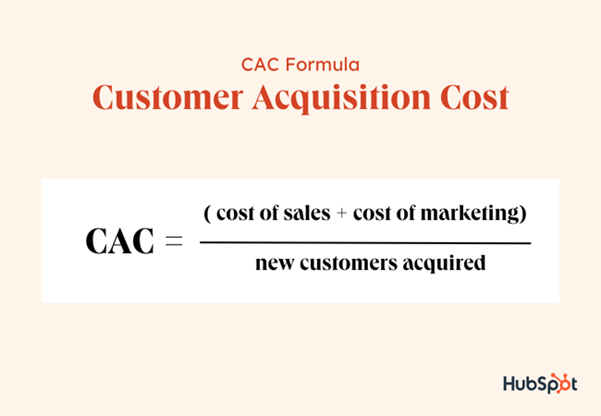

And while lean staffing issues may make this investment seem like an unnecessary luxury, when you compare the total cost of your sales and marketing efforts in your customer acquisition costs, versus the cost to retain your existing customers, it can make great business sense.

How improved customer experiences can drive lasting customer loyalty

While effective risk management and the adoption of automation tools are essential for keeping the supply chains running efficiently, the right inventory solution can help you boost profitability and deliver ongoing outstanding customer service.

Customer expectations are evolving—and fast. If you’re only managing your own business processes for efficiency and cost, you’re not thinking big enough—and you’ll soon start to feel the impact.

To stay ahead of the curve and to nurture customers who are happy, satisfied, and loyal to your brand means putting your customers’ needs at the heart of your business, staying in touch, and where possible, delivering real-time personalized experiences.

Consumer expectations are rising as the value of their spending increases. Today, the line between you and your competitors doesn’t always come down to cost. The experience you provide as well as the quality of your service and your products matter.

Having a better understanding of the customer journey, even across multiple organizations, departments, or systems that aren’t integrated, isn’t easy. But research shows that investing in this part of your business pays off.

Improving the customer experience can not only help you mitigate the potential negative impact of supply chain and inventory issues, but it can also directly impact your bottom line and improve your profit margins.

Businesses that provide quality customer experiences benefit from increased revenue as well as cost reductions in their HR and customer acquisition costs.

Discover how to take the stress out of supply chain and inventory challenges

Download this free guide to learn how to:

- Prevent stock outs and overstocks

- Understand and prioritize your top-performing items

- Analyze your weeks of supply and sell-through velocity

- Implement location-based analysis across your items

- Hone your promotion strategy

- Be proactive in your internal and external communications

Ask the author a question or share your advice