Strategy, Legal & Operations

The importance of the circular economy to the food industry

What are the current issues in the food industry? It supports a fast-growing population, fuelling economic development and urbanization for decades. s...

In light of recent events and the effects of businesses reevaluating their supply chains, what are the current issues the food industry is facing and how can new systems help solve these problems?

The food and beverage ecosystem and supply chain support a fast-growing population and have fueled economic development and urbanization for decades.

However, the productivity gains come at a cost due to the linear nature of food production which extracts finite resources. The current food production model is wasteful and polluting – and harms natural systems. Also, the impact of an ever-growing population and regulatory requirements are forcing food and beverage manufacturing leaders to change the way they work.

The circular economy could help. A traditional linear economy is where you make, consume, and throw away. Moving to a circular economy is all about creating a circle where you design out waste and pollution by keeping products and materials in use for as long as possible, finding ways to create new resources from what you discard.

The linear economy creates waste through a model that flows as take, make, use, dispose. Meanwhile, a circular economy eliminates waste through a cyclical model: make, use, return, recycle, reuse, make.

Through shifting to a circular economy for food production, you could see massive economic and environmental benefits across the food value chain and broader society.

As more and more industries embrace sustainability in their business models, for food and beverage manufacturers embedding circular economy principles means you’ll want to cut waste and therefore preserve the value of resources such as raw materials, water, and energy.

How to change manufacturing practices to embrace a circular economy

Build better manufacturing processes

Organizations can minimize waste by optimizing manufacturing processes through better technology and workforce training. Companies could also recycle food that would usually be wasted back into the production line, or create new products with leftover byproducts and ingredients.

Companies could look at putting in place regenerative approaches to food production and ensure that they cultivate food in a way that enhances, rather than degrades the environment. Regenerative agriculture focuses on topsoil regeneration, which includes recycling farm waste, cover cropping, crop rotation, and mixed farming.

Design and marketing healthier food options

In the circular economy, companies can explore changing food design and marketing to ensure food production processes are more efficient and effective. For instance, plant-based proteins require less natural resources, such as soil and water, than their animal counterparts.

Changes to make the food and beverage industry more circular rather than linear will need collaboration between food manufacturers and the rest of the food value chain.

Redistributing non-sellable food

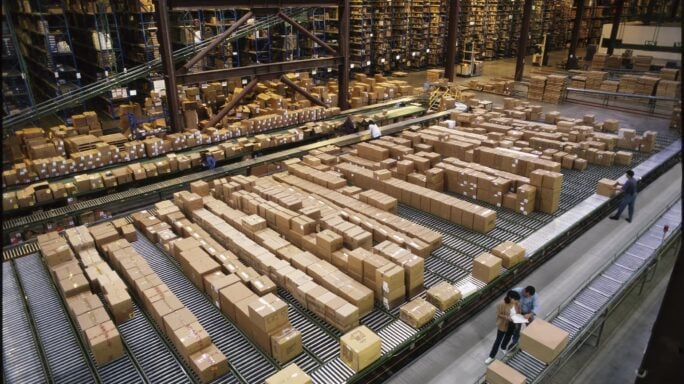

Across the supply chain, food losses seem to be inevitable as food and packaging are easily damaged as they go across land and sea. Yet much of this food is still edible, even if not necessarily suitable for sale. Food and beverage manufacturers can find alternative channels such as food donation partners and markets, to redirect this surplus food.

Recycling animal byproducts

Roughly 50% of an animal is considered inedible by Americans. In essence, rendering is a form of recycling that has been around for a long time and can reclaim the unused meat, bone, and fat for products such as pet food and biofuels. The manufacture and trade in rendered products are already an essential component of the agricultural economy of the US.

For example, biodiesel production reduces fossil fuel dependence and use. Rendered protein products can be used for fertilizer or as a soil conditioner, providing an alternative to chemical fertilizers.

Using environmentally friendly packaging

Food and beverage manufacturers could make more use of sustainable packaging – think bio-based recycled plastic or reusable transport and product packaging, for example.

Martin Leeming is the CEO of Trakrap, a British company that produces end-of-line packaging machinery for food manufacturers, supplying grocery retailers. Specifically, these machines create the packaging used to transit from a food manufacturer to the grocery retailer–such as tray and shrink wrap, holding a batch of tins or cans.

For more than 15 years, Trakrap has worked on ways to make packaging more sustainable, together with minimizing the amount needed to protect and display products. The company has built a system that uses a bespoke film to wrap products with or without trays. There is no requirement for heat and a vast reduction in the amount of corrugate needed.

Leeming says, “The principle for us was that it has to be more environmentally friendly. It has to cost less, too. And the way to achieve that is to use less of everything, less energy, less plastic, less cardboard, and that way you can deliver on both fronts.”

The war on plastic

When asked if this is why food manufacturers want to do business with the company, Leeming said, “It can be either of those, but I also feel that it can be misdirected. Retailers are driving an agenda which is not necessarily in line with the circular economy or sustainability.”

Leeming explained that supermarkets were being pressured by a ‘war on plastic,’ which wasn’t necessarily helping climate change, and is more about public pressure.

Plastic is a versatile material that keeps food fresh and protects it. But when plastic gets out into the environment, it can be very harmful to wildlife precisely because it doesn’t break down.

But from a carbon footprint and climate change point of view, it’s very, very effective for the same reason – it doesn’t take much energy to make it and doesn’t break down, so it doesn’t release its carbon back into the environment.

On the other side of the coin is cardboard, which is very intensive in terms of energy to produce. When it’s composted, it releases its carbon back into the atmosphere. But nobody has a problem with it being out in the environment because it doesn’t harm animals.

That said, Leeming said there is a tremendous amount of confusion about what we’re trying to achieve globally, whether it’s through the circular economy or sustainability.

He said, “A lot of [the war on plastic] is driven by the customer perception of doing the right thing. So, this has caused huge amounts of confusion in packaging for food manufacturers and supermarkets who want to do the right thing, but are not sure what the right thing is.”

What’s the solution? Leeming says: “We have to start being a bit clearer about the circular economy, sustainability, and climate change as being the three significant objectives, and where plastic fits into that.

“Plastic needs to be in a circular economy where it never gets out into the environment and used in a way that reduces its carbon footprint. There are billions of packs being transported into supermarkets every year, not millions. So, it’s a big, big, big opportunity both to address climate change and to improve the circular economy.”

The role of technology in the circular economy

It is Industry 4.0 and technology which makes it possible for TrakRap to do what they do – it allows the company to develop their technology through the control that digitization provides.

Leeming says, “Digitalization has allowed us to get the product to market much quicker than we would have been able to do through traditional means.”

For example, the machines that TrakRap employs to process its end-of-line packaging were first built digitally, which meant they could iron out issues before physically making them. Leeming said that it helped TrackRap get the product 50% quicker to market, and 40% cheaper.

TrackRap uses a servitization or pay-per-use model. It retains ownership of the machines, but this allows them to manage, reuse, refurbish, and re-manufacture the equipment they provide. Servitization is very important to the circular economy, as it means there is little to no waste when it comes to the product businesses can offer.

Leeming says, “The machine itself gets recycled as many times as we need. We think of our service as being more of a software platform. The customer doesn’t pay any more service and maintenance.

“Because we’ve got a digital twin, we can monitor our machines, and their performance remotely and massively reduce the number of road miles and time that service engineers have to go out and fix things as well. So the digitalization process allows new financial models which massively benefit the circular economy.”

Ask the author a question or share your advice